|

|

|

|

| Housing and Sleeve for Offshore Drilling Equipment | Automotive Brade Adjuster | Rifle Cannon | Sludge Valve for Mining Industry |

Menu

Nitreg®-C is based on the proven Nitreg® potential-controlled nitriding technology, whose ability to control processes and produce the desired properties of the nitrided layer has revolutionized the whole concept and practice of nitriding. Nitreg®-C has shorter process cycle times than Nitreg® for the same expected specifications and is carried out predominantly on carbon and low alloy materials.

It is often specified in industrial applications on the merit of its being an environmentally friendly but equivalent alternative to salt bath nitrocarburizing.

The advantage of a KN and KC controlled technology is best evidenced when increased wear and/or corrosion resistance is sought. Such properties of the nitrided case are not only influenced by the thickness and relative phase composition of the WL, but also strongly depend on the relative level of porosity developed in the WL.

Not sure which process or service is right for you?

Contact our global team of heat treat experts and let them guide you or

fill out the contact form to put you in touch with one of our experts!

|

|

|

|

| Housing and Sleeve for Offshore Drilling Equipment | Automotive Brade Adjuster | Rifle Cannon | Sludge Valve for Mining Industry |

Nitreg®-C is a nitrocarburizing process that involves the diffusion of carbon and nitrogen into the steel surface simultaneously. The purpose of this treatment is to create a hardened superficial layer, enhancing wear and corrosion resistance, or improved fatigue resistance of treated steel or cast-iron parts, without distortion of shape or dimensional changes. In order to maintain a proper concentration of nascent nitrogen and carbon at the surface of metal, Nitreg®-C technology utilizes the Nitriding and Carburizing Potentials (KN and KC) control concept.

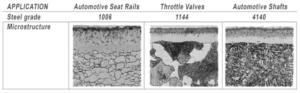

Example of various porosity levels achieved through KN control

Nitrocarburizing is mostly used on carbon steels and low alloy steels. It is also praised for its benefit on hot work tool steels.

A surface exposed to a nitriding medium will generally form two distinct layers. The outside layer is called a compound layer (or white layer) and its thickness generally falls between zero and 0.001” (25 µm). Underneath the white layer we have a diffusion case or diffusion zone. Both together comprise what is generally referred to as the case. However, depending on the material and its original pre-process hardness there will be very significant differences between the properties of these layers.