Menu

NITREG® is a modern heat-treating process, capable of meeting the metallurgical requirements of all nitriding specifications that may have been originally written for salt bath, plasma or traditional gas nitriding. The ability to control the concentration of nitrogen in the surface allows the user to control the growth of the compound layer virtually independently from developing a desirable diffusion zone. This approach facilitates not only meeting specification requirements, but it also makes it possible to improve on them by allowing for tighter tolerances, particularly regarding the thickness and properties of the compound layer.

The NITREG® Advantage

|  |  |  |  |

| POWER GENERATOR TURBINE | FORGING DIE | EXTRUSION DIE | AUTOMOTIVE BEARING SUPPORT | 3D-PRINTED NOZZLE |

Nitriding is a process of diffusing nitrogen atoms into the metal surface. Nitrogen is plentiful on Earth, but in nature it exists as a two-atom molecule which is chemically inert and too large to penetrate the surface. Therefore, nitriding technologies focus on the source of nascent (atomic) nitrogen.

The main objective of nitriding is to increase the hardness of the component’s surface by enriching it with nitrogen. Regardless of the method, nitriding is a process of diffusing nitrogen into the metal and diffusion, once individual nitrogen atoms have penetrated the surface, continues as long as the temperature is high enough and there is a fresh supply of nascent nitrogen on the surface. In other words, the diffusion is essentially the same in all nitriding, while the difference lies in the supply of nitrogen, which has a fundamental influence on the resultant surface properties.

Generally speaking, all ferrous alloys including stainless steels, cast irons, and even titanium alloys are capable of being nitrided. However, alloys have unique characteristics when it comes to surface conditions, the natural speed of diffusion and propensity to form nitrides. Therefore, we must bear in mind that even a correctly configured nitriding process will produce significantly different results on dissimilar materials. Consequently, certain users may have insurmountable difficulties, particularly if their methodology is lacking and/or their knowledge and experience inadequate.

A surface exposed to a nitriding medium will generally form two distinct layers. The outer layer is called a compound layer (or white layer) and its thickness generally falls between zero and 0.001″ (25 µm). There is a diffusion case or diffusion zone underneath the white layer. Both layers make up what is generally referred to as the case. However, depending on the material and its original pre-process hardness, there will be significant differences between the properties of these layers.

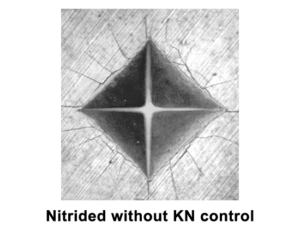

The images of two Vickers hardness test indentations shown below illustrate the difference between a controlled and uncontrolled process. The specimen on the left was produced in a traditional process and the surface cracking is indicative of the brittle layer. The specimen on the right is a product of a Nitreg® process where, despite the same hardness, cracks have not formed. The Nitreg® treated component is therefore more resilient with a very tough compound layer.

Such superior results can only be achieved by controlling the nitrogen concentration in the substrate and the modern approach is control of nitriding potential (KN). Proper understanding and application of the principles that tie nitriding potential (KN), temperature and time are the cornerstone of Nitreg® technology. An example of our ability to produce a variety of white layer/diffusion case combinations is shown in the following chart, Nitrided case combinations (PDF).

The ability to control the nitriding potential is gradually becoming a requirement as seen in AMS 2759/10 standards, for example.

In conclusion, Nitreg® is a modern process, capable of meeting the metallurgical requirements of all nitriding specifications that may have been originally written for salt bath, plasma or traditional gas nitriding.

| PROPERTIES / FEATURES | NITREG® Controlled Nitriding | Conventional gas | Salt bath | Plasma (Ion) |

|---|---|---|---|---|

| Cleaning (before) | Clean | Clean | Relatively clean | Very clean |

| Cleaning (after) | Not required | Not required | Absolutely required | Not required |

| Heating time | Short | Short | Very Short | Long |

| Parts positioning | Simple | Simple | Simple | Very complex / requires skill & experience |

| Nitriding of stainless steel | Possible | Not possible | Possible | Possible |

| Equipment operation | Very simple /fully automated | Relatively simple | Simple | Very complex / requires advanced skills |

| Temperature control/uniformity | Excellent | Good | Good | Difficult / insufficient / overheat possible |

| Control of nitriding potential | Yes | No | No | No |

| Control of % of ε and γ’ | Possible | No | No | Possible |

| Nitriding with no white layer | Possible | No | No | Possible |

| Porosity control | Possible | No | No | Possible |

| Repeatability of results | Excellent (regardless of load) | Possible (repetitive loads only) | Possible (repetitive loads only) | Possible (repetitive loads only) |

| Equipment maintenance | Simple | Relatively complex | Complex | Very Complex |

| Degree of pollution | Very Low | High | Extremely high | Very low |

Can’t find what you’re looking for? Please feel free to get in touch with our experts.